Uses and Characteristics of Double-Core Yarn

2025-02-26

Double-core yarn is a type of yarn made by twisting together two different types of long filaments as the core fibers, with short fibers serving as the outer wrapping material. Due to the differing properties of the two core filaments, they complement each other effectively, giving the yarn superior performance. For example, the cotton-wrap T400 + spandex combination—T400 is characterized by its excellent bulkiness.

Applications of spandex-covered yarn

2025-02-26

The use of spandex yarn in garments initially began with the three cuffs—neckline, cuffs, and leg openings—of knitted underwear. Previously, knitted underwear was mostly made from pure cotton, which, after washing, lost its elasticity and caused the cuffs to deform, resulting in both poor warmth retention and an unattractive appearance. Since the introduction of spandex, knitted underwear cuffs have adopted a weaving process that incorporates bare spandex yarn directly into the fabric.

Applications of filament core-spun yarn

2025-02-26

Core-spun yarn is a fine yarn spun by wrapping short fibers around a core filament. It combines the excellent physical and mechanical properties of both the core filament and the outer short fibers. Commonly used core filaments include polyester filament, nylon filament, and spandex filament. The outer short fibers typically include cotton, polyester-cotton blends, acrylic fiber, and wool. Core-spun yarn is primarily used for sewing threads, shirt fabrics, openwork fabrics, and stretch fabrics. Knitted fabrics or denim materials made from this type of core-spun yarn offer exceptional flexibility and comfort, allowing for free movement and a perfect fit when worn.

Characteristics of double-core spun yarn

2025-02-26

A double-core spun yarn is a type of yarn made by twisting together short fibers as the outer covering material and two filaments with different properties as the core filaments. Due to the contrasting properties of the two core filaments, they complement each other effectively, giving the yarn superior characteristics. For example, cotton-covered T400 plus spandex.

Explore various spinning methods for core-spun yarns.

2025-02-26

Core-spun yarn—a unique composite yarn—consists of an outer fiber layer tightly wrapped around a core yarn, resulting in a dense structure and uniform yarn characteristics. Thanks to its core-sheath construction, core-spun yarn not only transcends the single-function limitations of conventional ring-spun yarns but also combines the aesthetic appeal and hand feel of the outer fibers with the superior performance of the core yarn. This complementary combination of advantages gives core-spun yarn an overall superior quality, making it highly popular among consumers. Next, we will introduce several methods for spinning core-spun yarn.

2025-02-26

Recently, on the eve of the Chinese Lunar New Year holiday when the traditional market at the China Light and Textile City typically shuts down, as merchants from northern and southern regions gradually depart day by day, the consolidated freight forwarding market has already completely closed. Fabric transactions have noticeably declined, and some small- and medium-sized retail outlets have promptly sold out their winter stock in batches.

What kind of fabric is rabbit velvet core-spun yarn?

2025-02-26

Rabbit-fleece core-spun yarn is a fabric composed of 50% viscose, 30% nylon, and 20% polyester. This core-spun yarn combines the excellent properties of both filament core yarn and short fibers wrapped around the core. Rabbit-fleece core-spun yarn has an extremely wide range of applications and is suitable for many different types of products, primarily used in various woolen textiles, garments, knitted products, and other textile items.

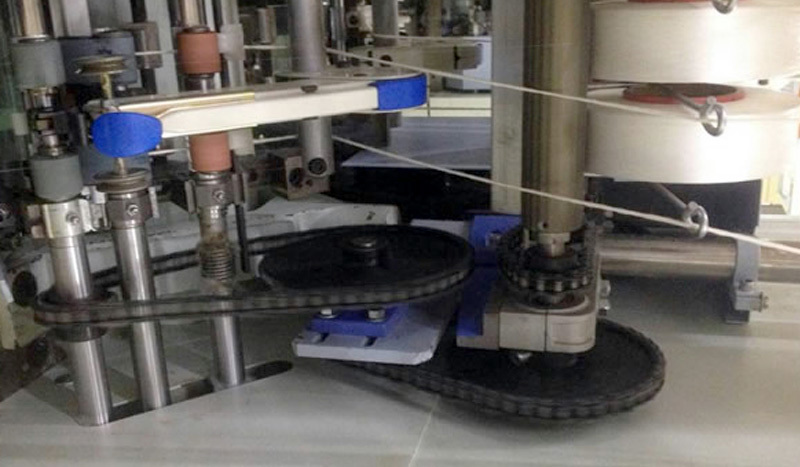

Jingwei Tianying CNC Core-Spun Bamboo-Effect Composite Yarn Device

2022-07-28

The core-spun bamboo-joint composite yarn machine is CNC-controlled, featuring a single operator interface that integrates multiple functions. It boasts a compact structure, aesthetic appeal, and practicality. It can independently produce core-spun yarns and bamboo-joint yarns, as well as simultaneously produce spandex-core bamboo-joint composite yarns and double-core bamboo-joint composite yarns.