Slider

Classification:

Specialized processing equipment and assembly lines for various types of roller bearings and slide bearings

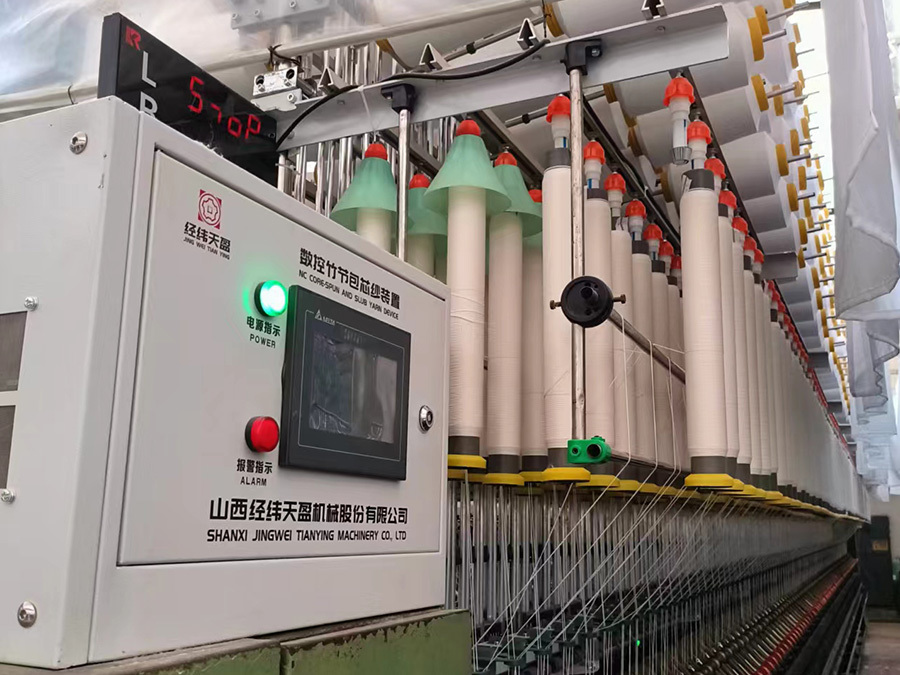

The company adheres to the corporate philosophy of "product innovation, customer first, people-to-people, and integrity management", and has long been committed to the development and production of series core-spun yarn devices.

Keywords: core-spun yarn

Customer Service Hotline: +86-18635455569

Detailed introduction

Graphic Details

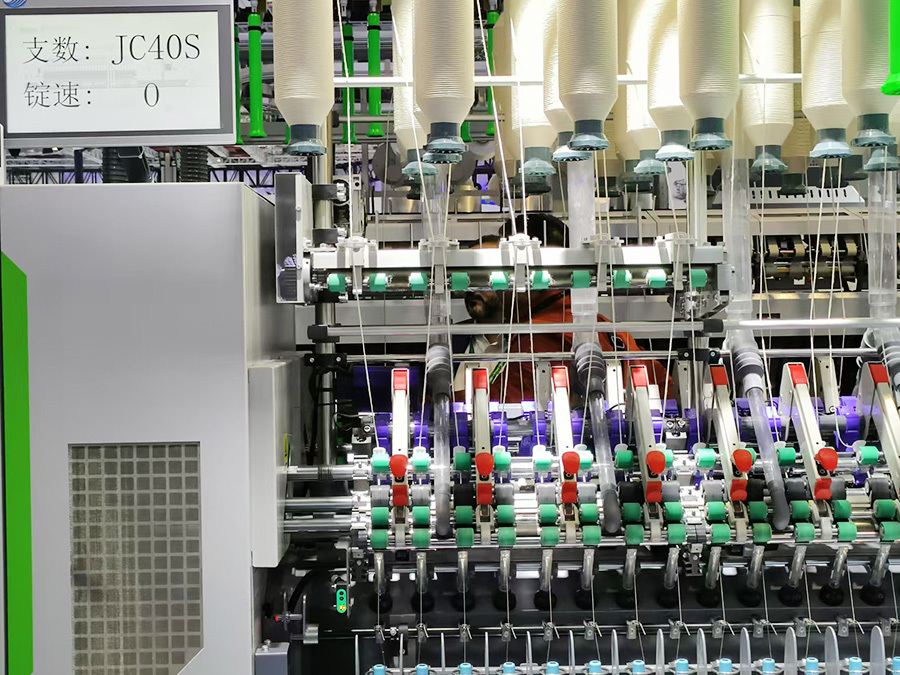

Precision Machining of Textile Machinery Parts - Focusing on core components of textile machinery, empowering efficient production

Why choose our textile machinery parts processing?

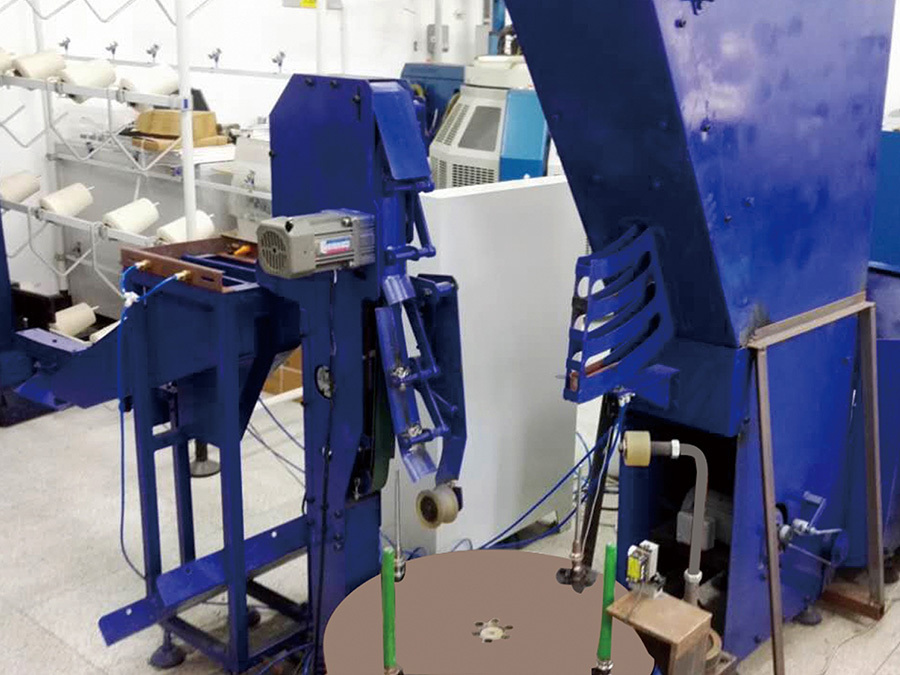

✅ Deep cultivation in the textile machinery field:Focusing on the processing of textile machinery rollers and slides for 30 years, proficient in the manufacturing of various roller and slide parts, adaptable to all types of equipment such as cotton spinning, chemical fiber, and non-woven fabrics!

✅ Full-process service capabilities:

•Custom design:Supports CAD/CAM drawing conversion, and quickly optimizes structural design.

•Small batch trial production:Flexible production line, minimum order of 1 piece, trial production cycle ≤7 days.

•Inspection and certification:Three-coordinate measuring instrument + metallographic analysis, conforming to ISO, JIS and other industry standards.

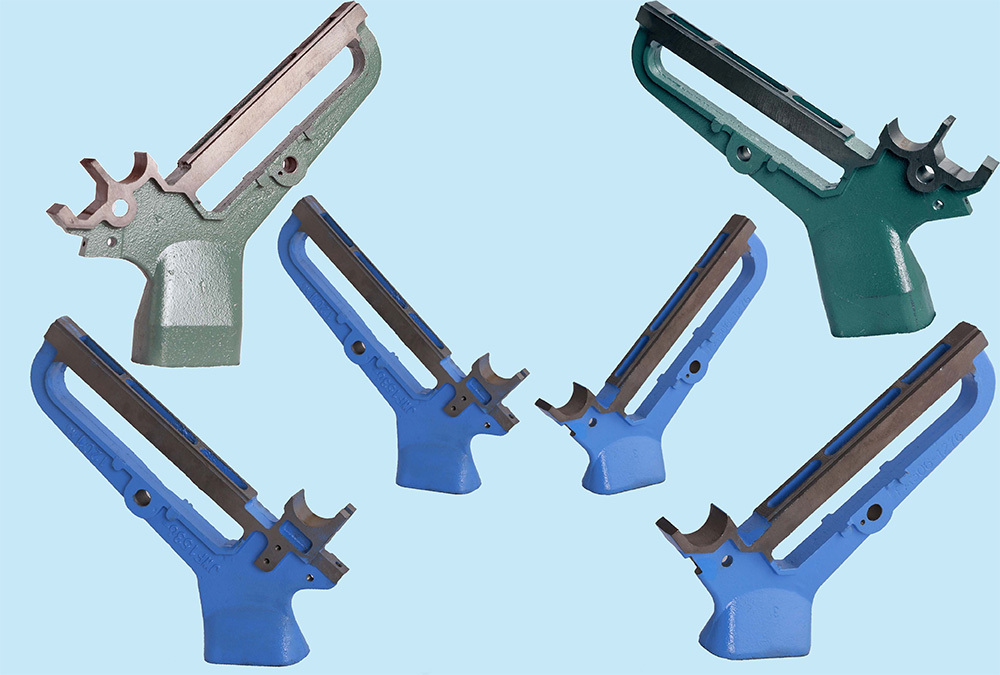

Core service scope

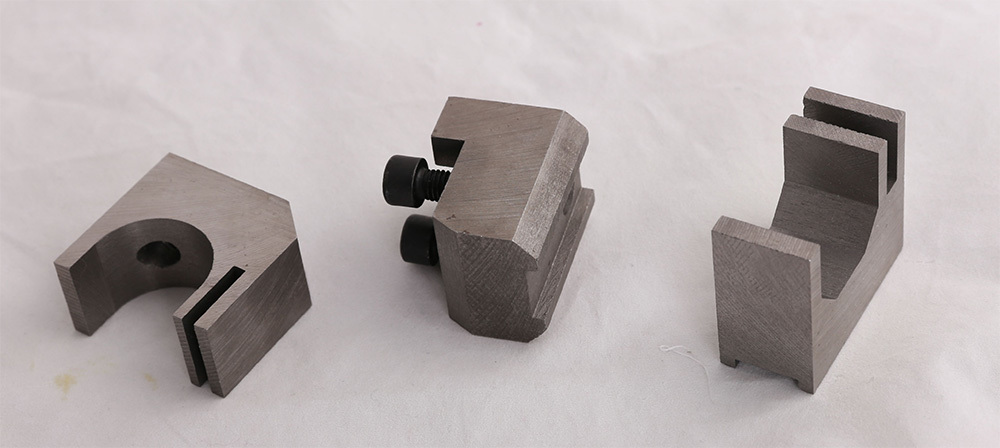

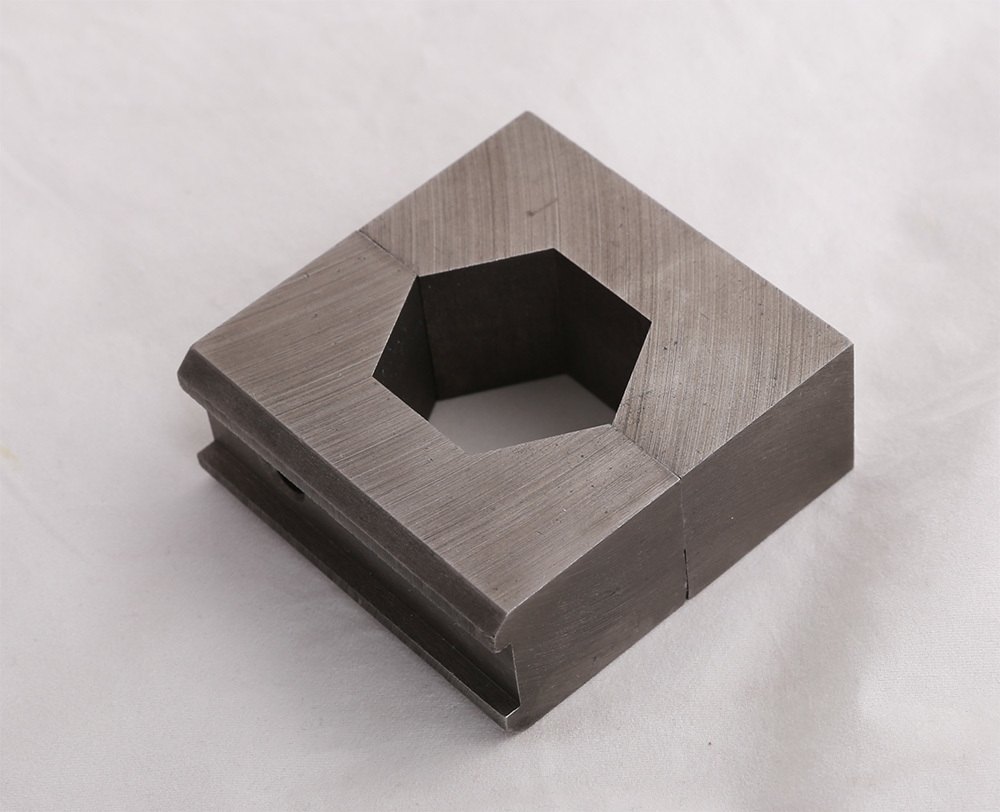

🔧Special part types

•Spinning equipment:Ring spinning roller seats, various compact spinning roller seats, various slide seats

•Accessory repair:Repair of old parts, Size correction, functional upgrade

🔧 Process coverage

• Professional processing equipment for various roller seats and slides, assembly line operation

Value created for customers

💡 Cost reduction and efficiency improvement

• Customized adaptation → Improves textile machinery operating efficiency and yield

• One-stop delivery → Eliminates the difficulties of coordinating multiple suppliers

💡 Quick response

• 24-hour technical consultation → Urgent orders are expedited

• Free process optimization suggestions → Reduce trial and error costs

Cooperation process

1. Submit requirements: Drawings/samples/parameter requirements

2. Customized solution: Process analysis + quotation (feedback within 24 hours)

3. Sample Confirm: Strict quality inspection, signing of acceptance agreement

4. Mass production: Transparent process throughout, on-time delivery

Previous:

Next:

Key words:

Online consultation

Related Products