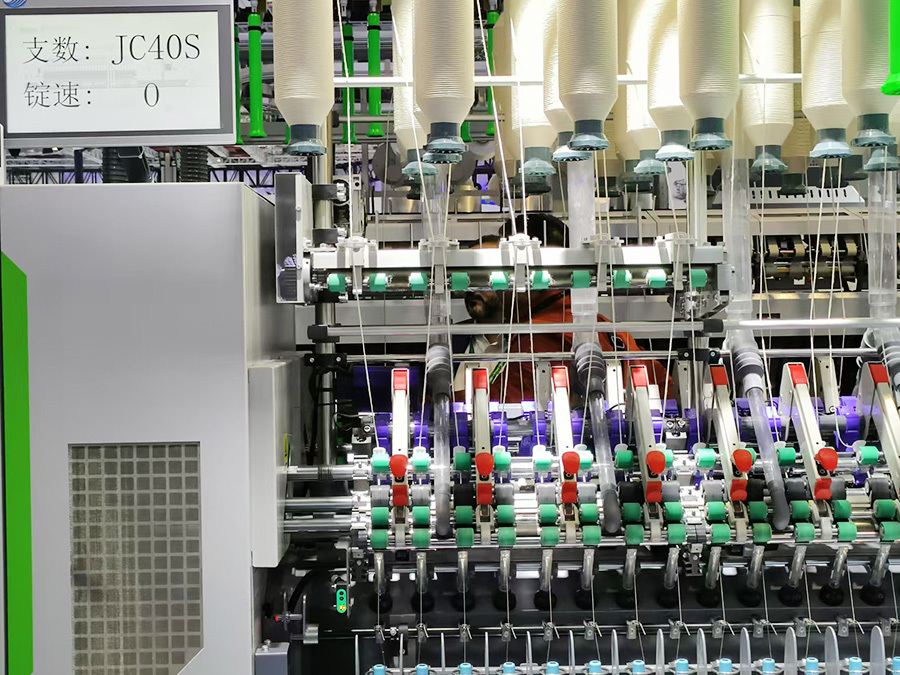

Numerical control core-spun yarn control interface

Classification:

NC-driving core spun yarn device with a servo motor is controlled by Pc which simplifies the variety change of yarn and is suitable for various core spun yarns with higher quality.

The company adheres to the corporate philosophy of "product innovation, customer first, people-to-people, and integrity management", and has long been committed to the development and production of series core-spun yarn devices.

Keywords: core-spun yarn

Customer Service Hotline: +86-18635455569

Detailed introduction

Graphic Details

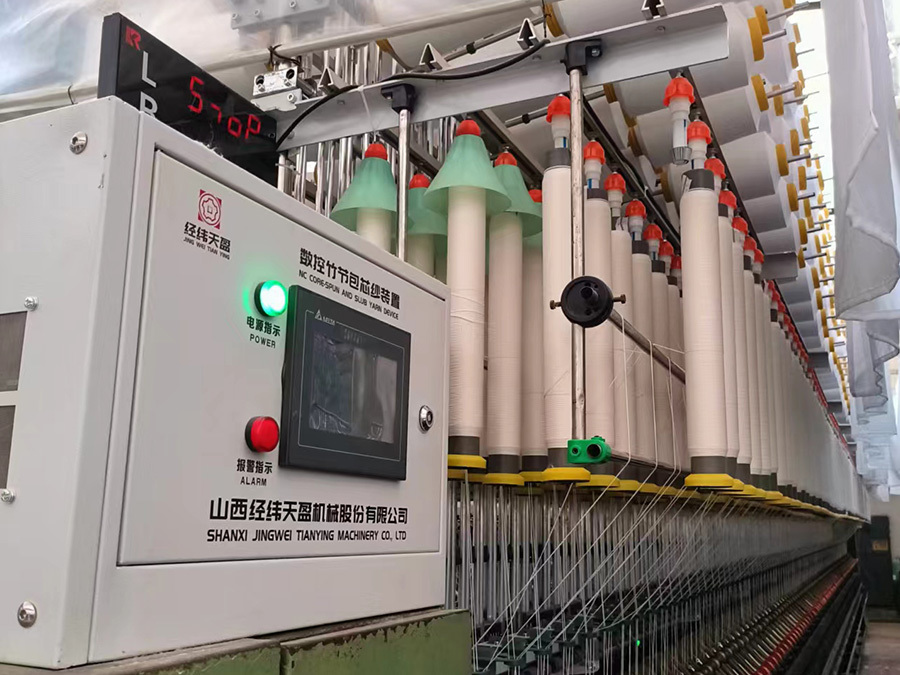

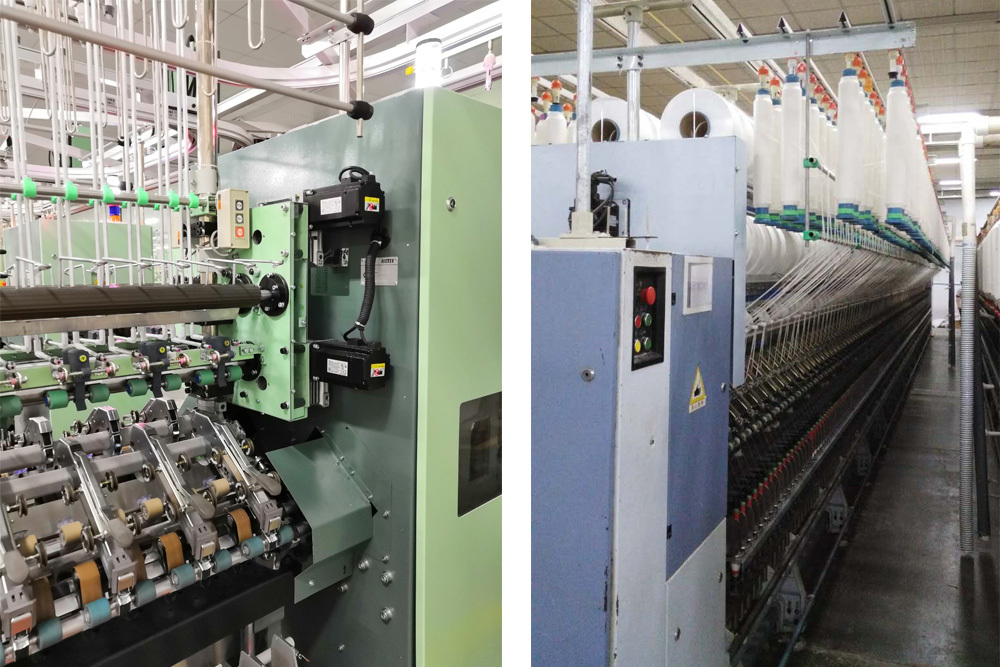

Elastic core spun yarn device

Driving system for elastic core spun yarn device

NC-driving core spun yarn device with a servo motor is controlled by Pc which simplifies the variety change of yarn and is suitable for various core spun yarns with higher quality.

Mechanical driving core spun yarn device drives the quide roller by a chain. It is of low cost, long service life and suitable for and mass production and less variety-changed production.

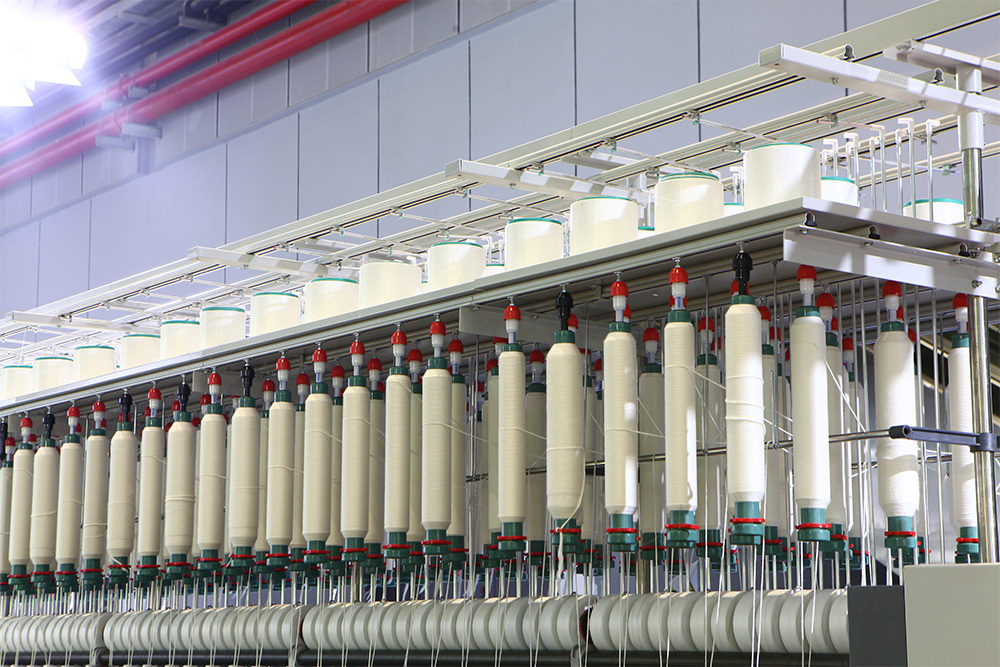

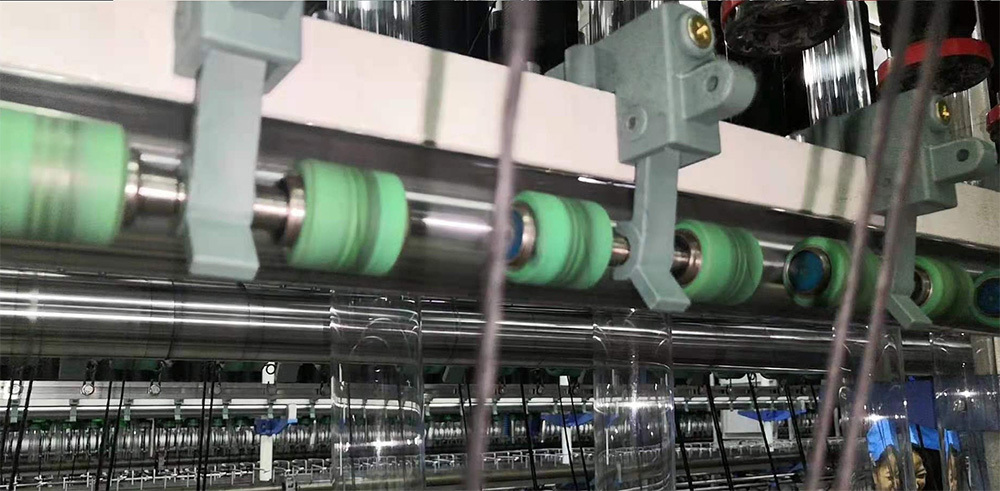

Main parts of elastic core spun yarn device

The device with aluminum groove: guide rollers with the hardened groove are durable and not easy to scratch and its delivery is accurate.

Stainless steel device: the stainless steel surface of guide roller is smooth and with a better cost-performance ratio.

The connection between the quide rolls is of the novel easy-dismounted construction. The bearing seat is adjustable, which is suitable for all kinds of cakes.

Creative thought and intelligent design

Automatic core stop unit is equipped with a sensor. The stop unit will stop the feeding when the core yarn is broken to avoid spinning the yarn without a core yarn.

Guide roll synchronous unit adopts the maanetic induction technology to monitor the feeding speed of the guide roll, which ensures the preset driving ratio and the best quality.

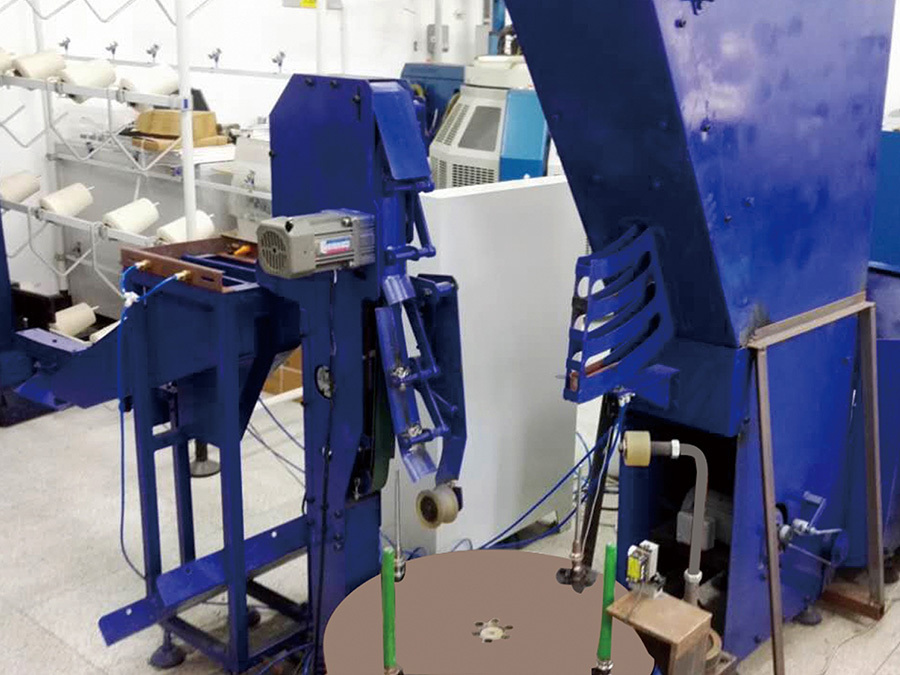

Rigid core spun yam

Yarn cake frame for rigid core spun yamn

The suspending cake frame is suitable for all kinds of cakes. External guide roll and internal guider can be adopted to deliver the core yarn.

The flat cake frame has compact structure and simplifies the assembly of the travelling cleaners. The internal guider is adopted to deliver the core.

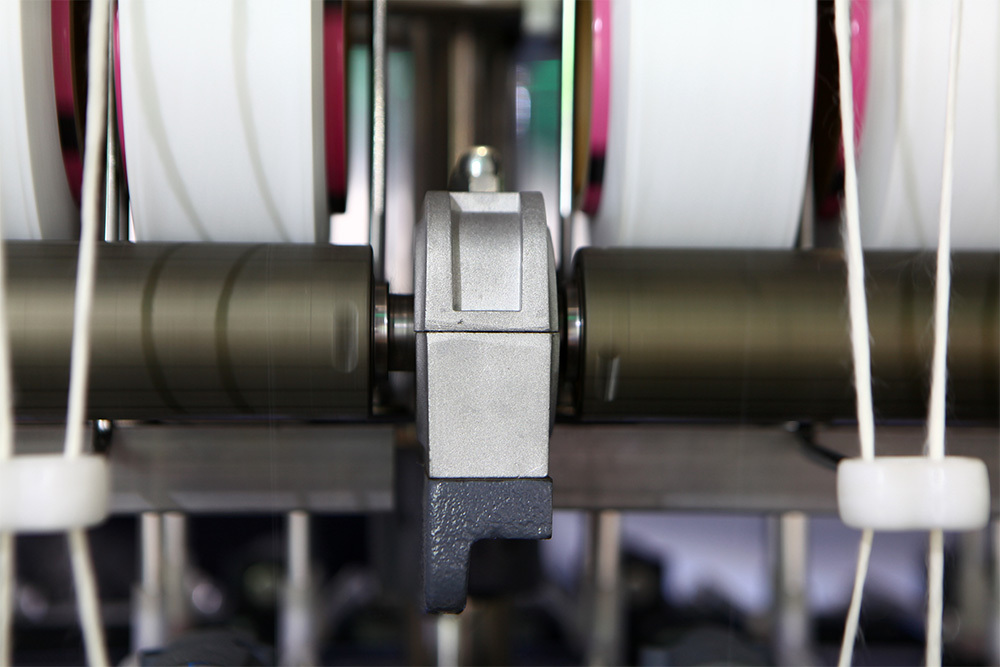

Delivery of rigid core spun yarn

Active delivery method: the servo motor is adopted to drive the pressure roll. The tension can be adjusted according the requirements from users. The tension is constant and the delivery is accurate.

Active delivery method: the servo motor is adopted to drive the pressure roll. The tension can be adjusted according the requirements from users. The tension is constant and the delivery is accurate.

Wire-moving system of rigid core spun yam

The built-in svstem: throuah wear-resistant aluminum alloy wire guide tube, can be drafted between two flver bobbins. The system can adopt suspension type or tile type wire frame and is well sealing and can effectively prevent fluffy catkins. lt is suitable for spinning high quality fabrics and high-grade denim yarn.

The external system: the core-yarn can be drafted by adopting the way of screw winding and adiusting the angle of special guidance yarn hook. The system can be adopted suspension type for easy to check the core-yarn.

Previous:

Key words:

Online consultation

Related Products